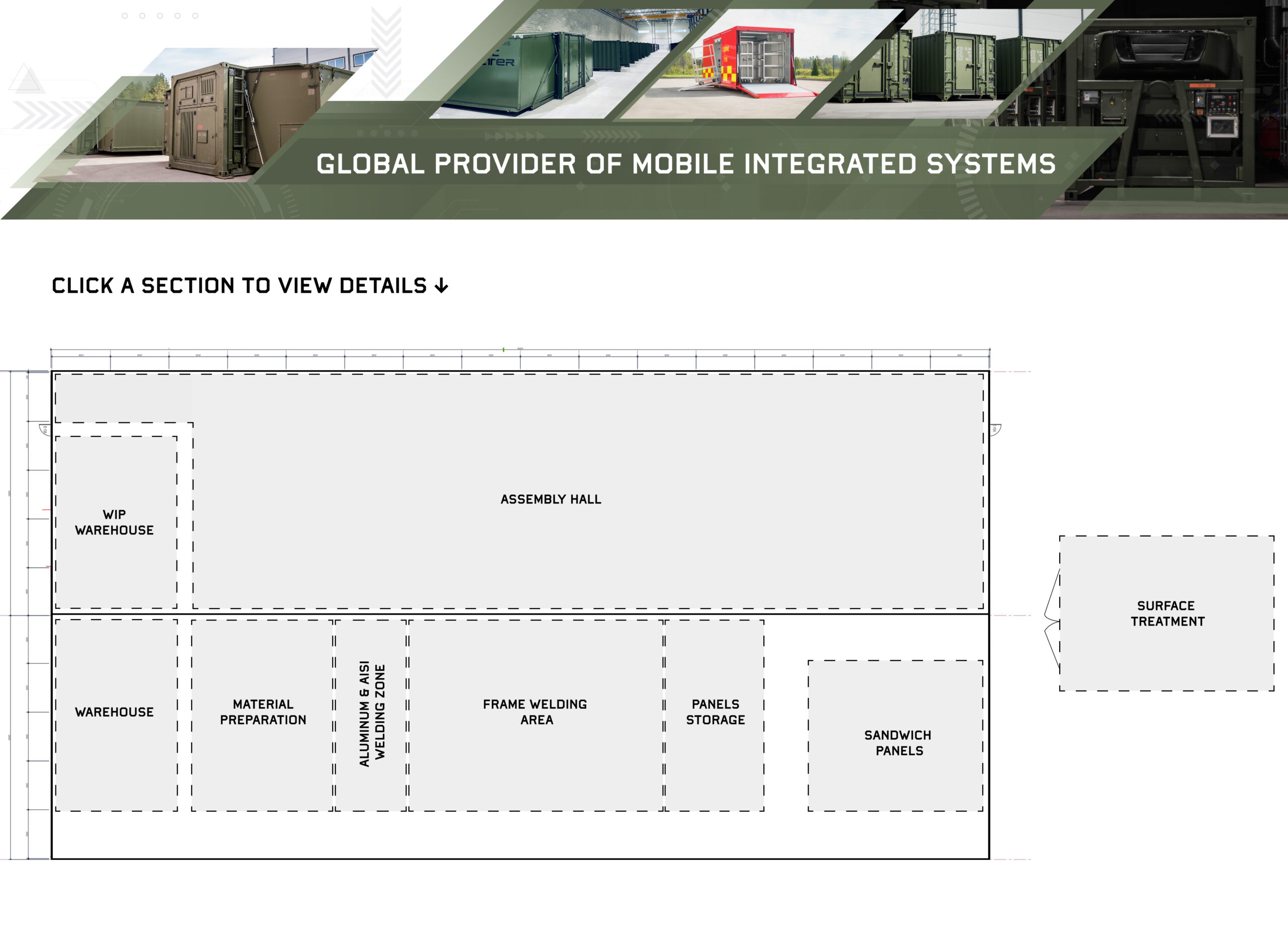

Factory Layout

• Established: 2011

• Located: in new and modern facilities in Tallinn, Estonia since 2020

• Production area: 5000 m²

• Quality and Environmental System certified to:

• ISO 9001

• ISO 14001

• Welding certificates:

• EN 1090-2 EXC3

• ISO 3834-2

• CSC: Product Certificates for Intercontinental Transport

• HAACP: Container Food Safety Self-Control Plan competences

• ATP: Refrigerated transport certificates compliance

Warehouse for Small Parts

• Closed facility for storage of small parts and components

• Shelves for material in sheets

• Racks for material in profiles

• Separated storage of different materials

• Customer property equipment handled on separate shelves

Preparation of Parts

• Sheet metal cutting guillotine

• Sheet metal bending machine

• Profile saw

• Machining of parts: lathe, drills, press bench

Frame Welding Area

• Two assembly tables for container frames from 5 to 40 FT container frames

• Subassembly tables for end frames

• Estimated production speed approx. 1 frame per week

• Welding certified ISO1090 and ISO3834

Sandwich Panels Storage Zone

• Dedicated area for storing sandwich panels before and after assembly

• Separate storage for foam and insulation materials

• Controlled environment ensuring material quality and protection

Sandwich Panels

• 4 tables used for gluing and bonding panels

• Space dedicated for preparation and finishing after panel assembly

• 650 m² production area optimized for efficient workflow

WIP Warehouse

• Dedicated storage area for painted frames and finished components

• Controlled environment preventing dust, scratches, or contamination

• Shelves organized by project and production batch

• Ensures safe handling and curing before final assembly

Assembly Hall

• 2,500 m² total production area

• 15 fully equipped workstations for assembly and testing

• Dedicated storage and handling for integration-ready components

• Separate zones for sub-assembly and electrical integration

Aluminum & AISI Welding Zone

• Dedicated area for aluminum and stainless steel structures

• TIG/MIG welding stations for precise and durable joints

• Certified welders ensuring high-quality results

Surface Treatment

• 5 × 12 m independent, dedicated paint booth area

• Controlled environment for temperature and humidity

• ISO-compliant ventilation and filtration systems

• Dedicated paint storage and handling facilities

• Supports multi-layer coating systems (e.g., epoxy, polyurethane, CARC)

• Processes aligned with ISO 12944 and EN 12206 standards